Product Description

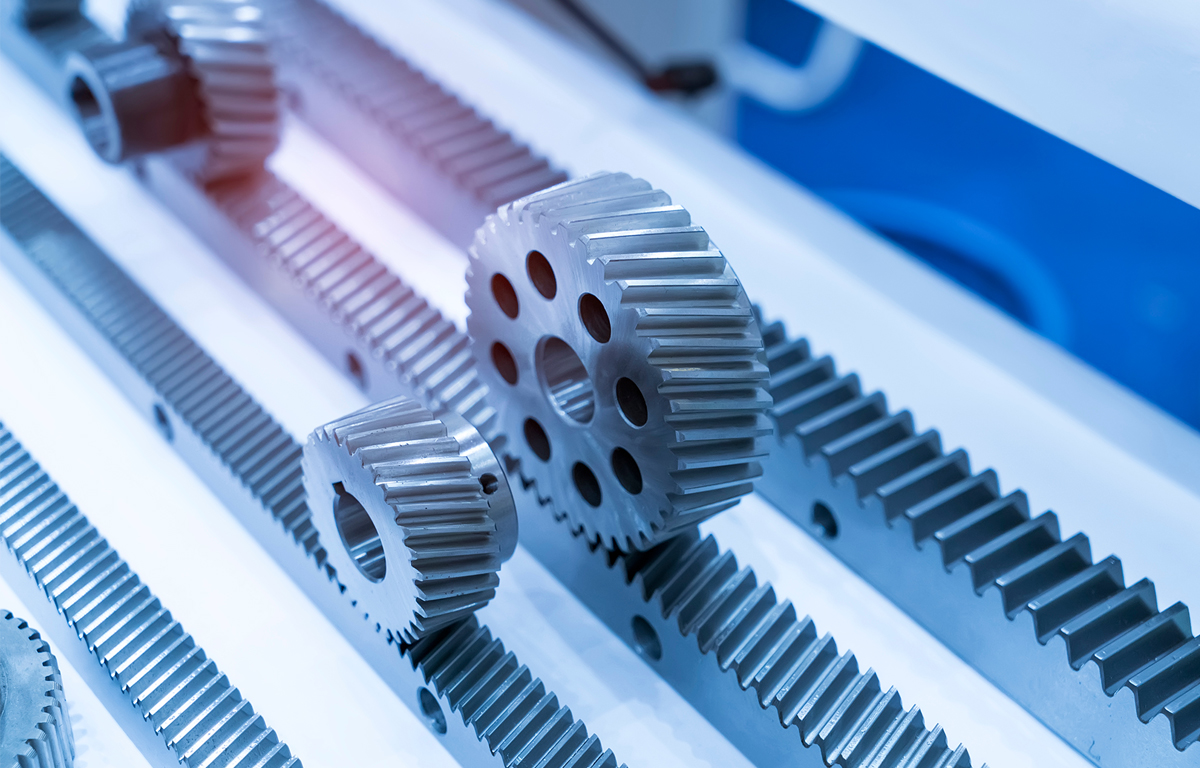

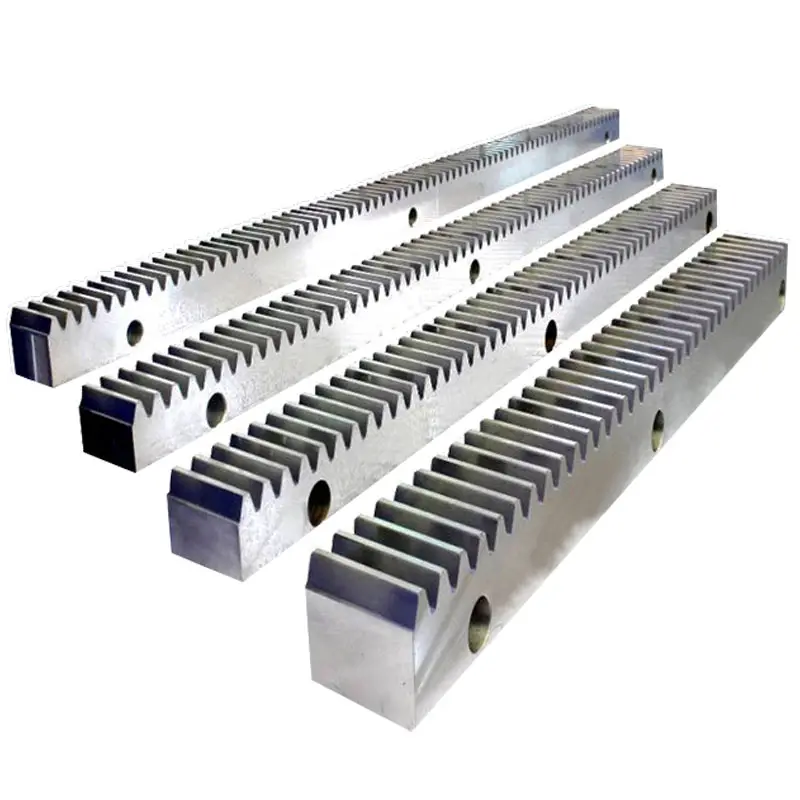

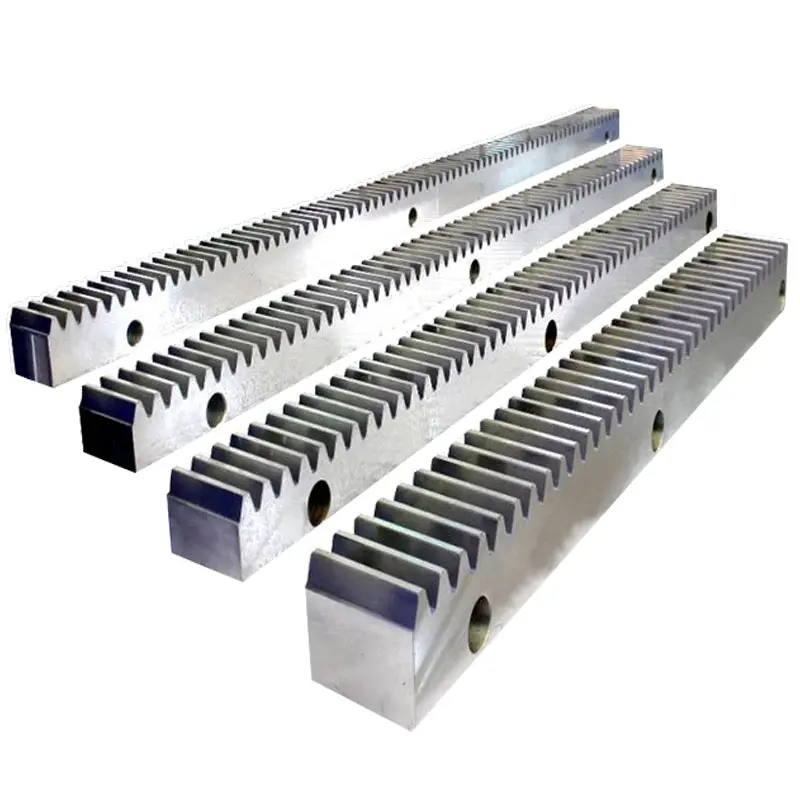

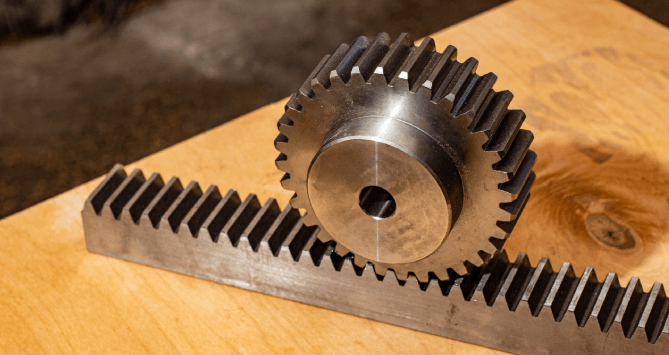

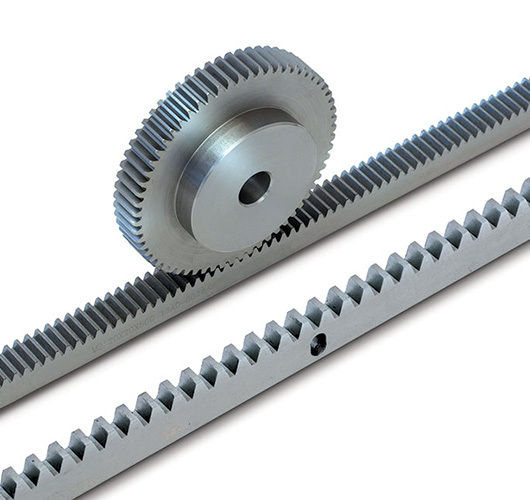

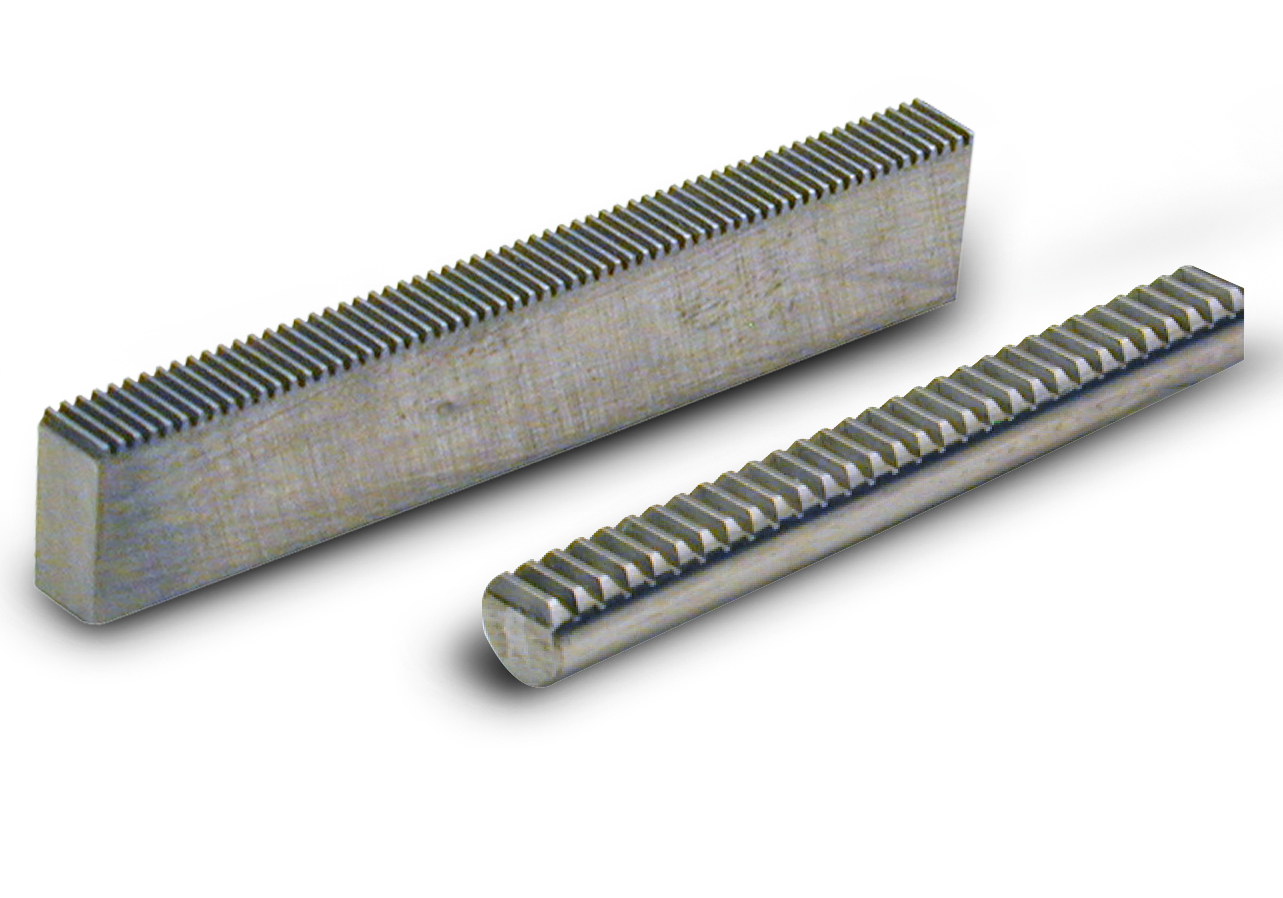

Round Gear Rack Ground Linear Flexible Industrial Durable China Manufacturer Stainless Steel Helical Spur Plastic and Pinion Steering Metric Pinion Gear Racks

Product Description

Click the picture to learn more

|

Spur gear |

Helical gear |

Double helical gear |

|

Miter gear |

Spiral Bevel Gear |

Straight bevel gear |

|

Internal gear |

Worm gear & worm shaft |

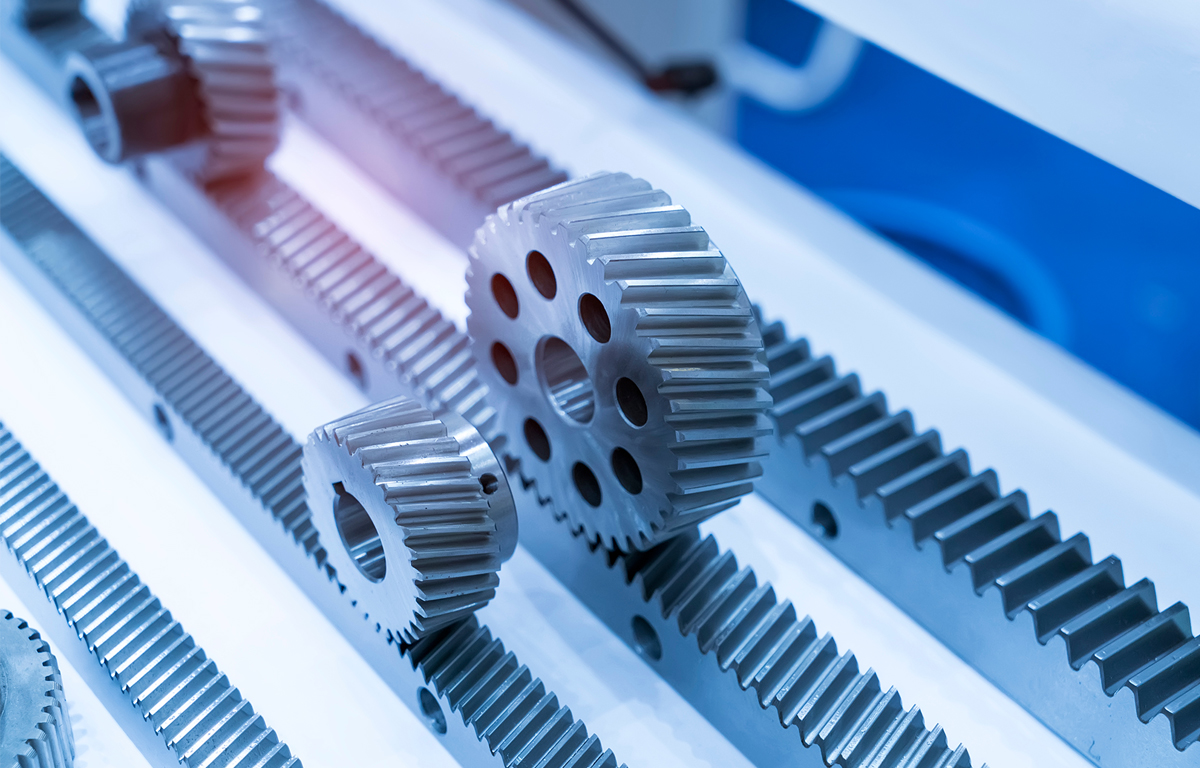

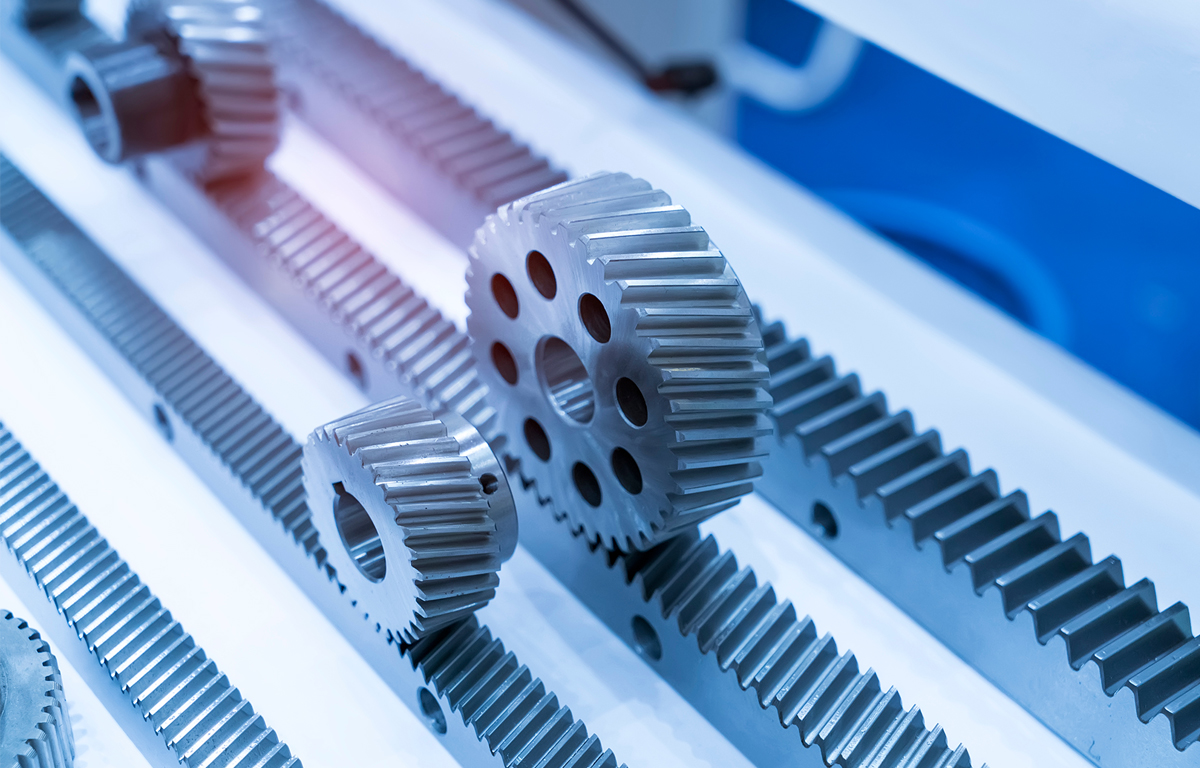

Gear rack |

We can produce large forging,casting and welding gears according to customer’s drawings.According to the working conditions and clients’ request,we also can do gear grinding,surface hardening,cemented and quenching,Nitriding and quenching,etc.

|

Material |

C45,40Cr,20CrMnTi,42CrMo, Copper, Stainless steel and so on as per your requests. |

|

Processing |

F.orging, Machining, Hobbing, Milling, Shaving, Grinding, Heat treatment….… |

|

Heat Treatment |

Carburizing,Induction,Flame,Nitriding….… |

|

Main Machines |

NC Gear Hobbing Machines, NC Gear Shapers(Gealson, Moude), NC lathe, NC gear Shaving machines, NC gear milling, Nc gear grinding |

Our company specializes in manufacturing custom-made large-scale gears for various industrial applications, employing advanced forging, casting, and welding techniques as per our clients’ exact specifications and technical drawings. We take pride in our ability to create gears that not only meet but exceed expectations in terms of durability and performance under demanding working conditions.

In addition to precision fabrication, we offer an array of post-processing services tailored to enhance gear longevity and functionality. These value-added treatments include:

-

Gear Grinding: Ensuring exceptional surface finish and high accuracy of tooth profiles for smoother operation and reduced noise.

-

Surface Hardening: Applying processes like induction hardening or flame hardening to form a hardened wear-resistant surface layer while preserving a tough interior core, ideal for gears subject to high loads and surface wear.

-

Cementation (Carburizing): A heat treatment process where carbon is diffused into the surface of the gear to increase its hardness, enhancing load-bearing capabilities without compromising toughness.

-

Quenching: Rapid cooling after heating to achieve the desired microstructure and mechanical properties, thereby improving hardness and strength of the gears.

-

Nitriding and Quenching: Nitriding involves introducing nitrogen into the surface layer to create a hard and wear-resistant case, often followed by quenching to further refine the material’s properties. This combination results in gears with superior fatigue resistance and improved service life.

Each of these processes is meticulously executed under strict quality control measures to ensure that every gear component produced meets stringent standards and client requirements. Our commitment to customization allows us to cater to diverse industries and unique operational environments, providing customers with gears that are specifically designed and treated to withstand their specific application demands.

Heat treatment:

Normalized / Annealed / Quenched / tempered

Surface Treatment:

painting,plating,polishing,black oxide,transparent anti-rust oil

Quality control:

UT,MT,RT,PT,chemical composition test,mechanical property test,etc.

Inspection:

1, Raw material certificate(material chemical composition) 2, Heat treatment sheet report

3, Dimension inspection report 4, UT test report

Delivery condition

Hot forged +Rough machined (black surface after Q /T)+ Turned

Competitive Advantage:

Quality control and management to the whole produce process, including ingot smelting, forging, heat treatment, machining and strictly final inspection prior to delivery.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do spur gear racks contribute to efficient and precise linear motion?

Spur gear racks play a significant role in achieving efficient and precise linear motion in various mechanical systems. They offer several advantages that contribute to the overall performance and accuracy of linear motion mechanisms. Here’s how spur gear racks contribute to efficient and precise linear motion:

- Direct Conversion of Rotational to Linear Motion: Spur gear racks provide a direct conversion of rotational motion into linear motion. When a spur gear, known as a pinion, meshes with the gear rack, the rotary motion of the pinion is translated into linear motion along the rack’s length. This direct conversion eliminates the need for additional mechanisms or complex linkages, reducing energy losses and improving overall efficiency.

- High Efficiency: Spur gear racks are known for their high mechanical efficiency. The teeth of the gear rack and pinion mesh in a straight line, resulting in efficient power transmission with minimal energy losses. The involute tooth profile commonly used in spur gear systems ensures gradual and smooth tooth engagement, reducing friction and minimizing power wastage. This high efficiency contributes to the overall energy efficiency of the linear motion system.

- Precise Positioning: Spur gear racks offer precise positioning capabilities, making them suitable for applications that require accurate linear motion. The teeth of the gear rack and pinion provide positive engagement, ensuring precise and repeatable positioning along the rack’s length. This allows for accurate control and positioning of loads, making spur gear racks suitable for applications such as CNC machines, robotics, and precision positioning systems.

- Low Backlash: Backlash refers to the slight clearance or play between mating gears. Spur gear racks can be designed with minimal backlash, ensuring accurate and responsive linear motion. The teeth of the gear rack and pinion engage tightly, minimizing any undesirable movement or backlash during direction changes or load reversals. Low backlash contributes to the system’s precision, especially in applications where accurate positioning and control are critical.

- Load Distribution: Spur gear racks distribute the load over a larger contact area compared to other linear motion mechanisms. The multiple teeth along the rack’s length distribute the load evenly, reducing stress concentrations and enhancing load-carrying capacity. This load distribution capability allows for the handling of higher loads while maintaining smooth and precise linear motion.

- Modularity and Scalability: Spur gear racks offer modularity and scalability, making them adaptable to various system requirements. Gear racks can be easily extended or shortened to achieve the desired linear travel distance. Additionally, multiple gear racks can be combined or stacked to achieve longer travel distances or parallel linear motion. This modularity and scalability make spur gear racks versatile and suitable for a wide range of applications.

- Reliability and Durability: Spur gear racks are known for their reliability and durability. The simple and robust design of gear racks, combined with proper lubrication and maintenance, ensures long-term performance and minimal downtime. Spur gear racks can withstand high loads, operate under demanding conditions, and provide consistent linear motion over extended periods, contributing to the overall reliability and durability of the linear motion system.

By leveraging the advantages offered by spur gear racks, engineers and designers can achieve efficient, precise, and reliable linear motion in a wide range of applications. The selection of suitable gear rack materials, tooth profiles, and proper maintenance practices further enhance the performance and longevity of the linear motion system.

Can spur gear racks be applied in automotive applications, and if so, how?

Yes, spur gear racks can be widely applied in automotive applications, playing essential roles in various systems and components. Their durable and reliable characteristics make them suitable for different automotive functions. Here’s a detailed explanation of how spur gear racks can be utilized in automotive applications:

- Steering Systems: One of the primary applications of spur gear racks in automobiles is in steering systems. Gear racks are used in rack and pinion steering systems to convert rotational motion from the steering wheel into linear motion to control the direction of the wheels. The gear rack is mounted on the steering shaft, and as the pinion gear rotates, it engages with the gear teeth on the rack, causing the rack to move linearly and turn the wheels accordingly. Spur gear racks offer accurate and responsive steering, ensuring safe and reliable maneuverability.

- Seat Adjustments: Spur gear racks are also employed in automotive seat adjustment mechanisms. They enable the linear positioning of seats to accommodate different driver and passenger preferences. Gear racks, along with a pinion gear or motor, are used to achieve the desired seat height adjustment, forward and backward movement, and reclining angles. The gear rack system provides smooth and precise seat adjustments, enhancing comfort and ergonomics in vehicles.

- Window and Sunroof Mechanisms: Gear racks are utilized in automotive window and sunroof mechanisms to provide controlled and reliable linear motion. The gear rack, along with a motor or manual crank, enables the raising and lowering of windows or the opening and closing of sunroofs. Spur gear racks ensure smooth and synchronized movement of the window or sunroof panels, enhancing convenience and ventilation in vehicles.

- Convertible Top Actuation: In convertible vehicles, spur gear racks are employed in the actuation of the convertible top mechanism. The gear rack, driven by a motor or hydraulic system, facilitates the controlled extension or retraction of the convertible top. Spur gear racks offer precise and synchronized linear motion, ensuring smooth and reliable operation of the convertible top mechanism.

- Transmission Systems: Spur gear racks can be utilized in certain automotive transmission systems, particularly in manual transmissions. Gear racks, along with a shifting mechanism, enable the linear movement of gears to engage different gear ratios. By sliding the gear rack, the transmission system achieves the desired gear selection, allowing for smooth and efficient power transfer from the engine to the wheels.

- Chassis and Suspension Systems: Spur gear racks can be employed in automotive chassis and suspension systems to facilitate various movements and adjustments. For example, they can be used in adjustable suspension systems to control the ride height and stiffness of the vehicle. Gear racks, along with hydraulic or electronic actuators, allow for precise and dynamic adjustments, enhancing handling, stability, and comfort in different driving conditions.

Overall, spur gear racks are essential components in automotive applications, providing reliable and precise linear motion in steering systems, seat adjustments, window and sunroof mechanisms, convertible top actuation, transmission systems, and chassis/suspension systems. Their robust construction and ability to handle high loads make them suitable for the demanding requirements of the automotive industry.

What are the advantages of using spur gear racks in mechanical systems?

Spur gear racks offer several advantages when used in mechanical systems. These advantages contribute to their widespread use and popularity across various industries. Here are some key advantages of using spur gear racks:

- Efficient Power Transmission: Spur gear racks provide efficient power transmission between the rack and pinion gear. The straight teeth of the rack engage with the pinion gear, allowing for smooth and direct power transfer. This results in minimal power loss, making spur gear racks an efficient choice for transmitting rotational motion into linear motion or vice versa.

- Precise Linear Motion: Spur gear racks deliver precise and controlled linear motion. The teeth on the rack engage with the pinion gear, ensuring accurate movement along the length of the rack. This precision is essential in applications that require accurate positioning, such as CNC machines, robotics, and automated systems. Spur gear racks allow for repeatable and reliable motion control.

- High Load Capacity: Spur gear racks are designed to handle high load capacities. The straight tooth design and the wide contact area between the rack and pinion gear enable them to withstand substantial forces. This makes spur gear racks suitable for applications that involve heavy loads or high torque requirements, such as material handling systems, industrial machinery, and automotive components.

- Simple and Compact Design: Spur gear racks have a relatively simple and compact design. They consist of a straight bar with teeth along one side, along with a pinion gear. This simplicity makes spur gear racks easy to manufacture, assemble, and maintain. The compact design allows for efficient space utilization in mechanical systems, making them suitable for applications with limited space constraints.

- Cost-Effective: Spur gear racks are cost-effective compared to other types of gearing systems. Their simple design and ease of manufacturing contribute to lower production costs. Additionally, spur gear racks have a long service life and require minimal maintenance, reducing overall operating costs. These factors make spur gear racks a cost-efficient choice for many mechanical systems.

- Versatility: Spur gear racks are highly versatile and can be used in a wide range of applications. From automotive steering systems to industrial machinery and robotics, spur gear racks find utility in numerous industries. They can be customized to meet specific requirements by adjusting parameters such as gear ratios, tooth profiles, and materials. The versatility of spur gear racks makes them adaptable to various mechanical systems.

- Reliability and Durability: Spur gear racks are known for their reliability and durability. The design and tooth engagement of spur gear racks ensure robust performance and resistance to wear and tear. When properly lubricated and maintained, spur gear racks can operate smoothly and reliably for extended periods. This reliability and durability make spur gear racks suitable for demanding applications that require continuous and dependable operation.

These advantages make spur gear racks a popular choice in mechanical systems that require efficient power transmission, precise linear motion, high load capacity, and cost-effectiveness. The simplicity, versatility, and reliability of spur gear racks make them a fundamental component in various industries and applications.

editor by Dream 2024-05-15

China wholesaler High Precision C45 Steel Flexible Gear Racks worm gear winch

Product Description

Product Description

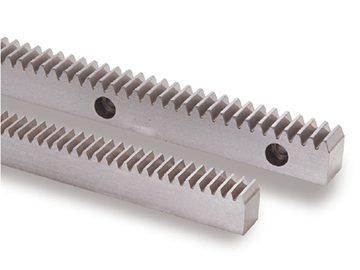

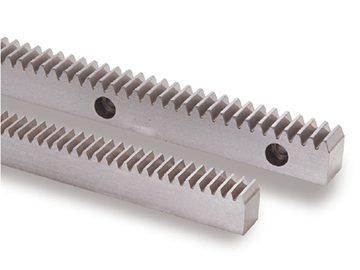

|

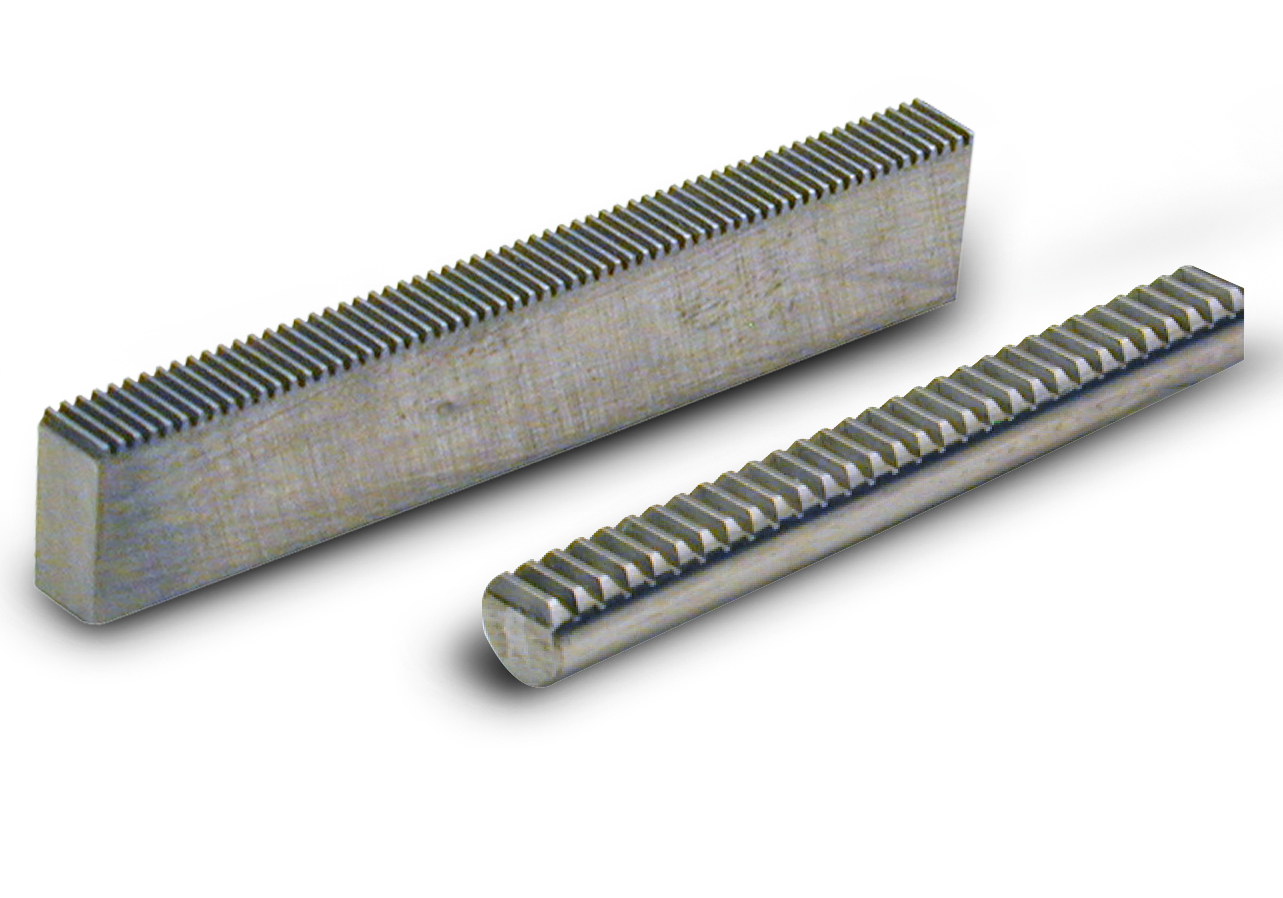

Products |

Gear rack |

|||

|

Precision grade |

DIN5, DIN6, DIN7, DIN8, DIN10 |

|||

|

Material |

C45 steel, 304SS, 316SS, 40CrMo, nylon, POM |

|||

|

Heat treatment |

High frequency,Quenching/Carburization, Teeth hardened |

|||

|

Surface treatment |

Zinc-plated,Nickle-plated,Chrome-plated,Black oxide or as you need |

|||

|

Application Machine |

Precision cutting machines. Lathes machine Milling machines Grinders machine Automated mechanical systems Automated warehousing systems. |

|||

|

Produce Machine |

CNC engine lathe CNC milling machine CNC drilling machine CNC grinding machine CNC cutting machines Machining center |

|||

|

Workstyle |

Execution is more preferred than empty talk. |

|||

|

Stock Gear Rack Type |

Specification |

Color |

|

Helical gear rack |

M1 15*15*1000mm |

White |

|

M1.5 19*19*1000mm |

White |

|

|

M2 24*24*1000mm |

White |

|

|

M3 29*29*1000mm |

White |

|

|

M4 39x39x1000mm |

White |

|

|

Spur gear rak |

M1 15*15*1000mm |

Black |

Rack Assembly

To assemble connected racks more smoothly, 2 ends of a standard rack would add half tooth which is convenient for next half tooth of next rack to be connected to a complete tooth. The following drawing shows how 2 racks connect and tooth gauge can control pitch position accurately.

With regards to connection of helical racks, it can be connected accurately by opposite tooth gauge.

1. When connecting racks, we recommend lock bores on the sides of rack first, and lock bores by the sequence of the foundation. With assembling the tooth gauge, pitch position of racks can be assembled accurately and completely.

2. Last, lock the position pins on 2 sides of rack; the assembly is completed.

Test

Use Coordinate Measuring Machine to test the precision and hardness of gear rack and pinion

Packaging & Shipping

Small quantity: We will use carton box.

Big quantity: We will use wooden cases.

Company Profile

ZheJiang Haorongshengye Electrical Equipment Co., Ltd.

1. Was founded in 2008

2. Our Principle:

“Credibility Supremacy, and Customer First”

3. Our Promise:

“High quality products, and Excellent Service”

4. Our Value:

“Being Honesty, Doing the Best, and Long-lasting Development”

5. Our Aim:

“Develop to be a leader in the power transmission parts industry in the world”

|

6.Our services: |

1).Competitive price |

|||

|

2).High quality products |

||||

|

3).OEM service or can customized according to your drawings |

||||

|

4).Reply your inquiry in 24 hours |

||||

|

5).Professional technical team 24 hours online service |

||||

|

6).Provide sample service |

||||

Main products

Machines

Exbihition

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Manufacturing Method: | Hobbing |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What safety considerations should be kept in mind when working with spur gear racks?

When working with spur gear racks, it is important to keep several safety considerations in mind to ensure the well-being of personnel and the proper functioning of the equipment. Here are some key safety considerations to be aware of:

- Entanglement and Pinch Points: Spur gear racks have rotating parts and moving components. It is crucial to be cautious of entanglement and pinch points during installation, operation, and maintenance. Keep hands, clothing, and other loose items away from the gear rack and associated machinery while it is in motion. Use appropriate guards or protective covers to prevent accidental contact with the gears and rotating parts.

- Lubrication and Maintenance: Proper lubrication is essential for the smooth operation of spur gear racks. Follow the manufacturer’s guidelines regarding the type and amount of lubricant to be used. Regularly inspect and maintain the gear rack system to ensure that it remains in good working condition. Replace worn-out or damaged components promptly to prevent potential hazards and maintain optimal performance.

- Load Capacity and Overloading: Spur gear racks have specific load capacities that should not be exceeded. It is important to understand the load limits of the gear rack and ensure that the equipment or machinery it is integrated with operates within those limits. Overloading can lead to premature wear, tooth failure, and potential accidents. Refer to the manufacturer’s specifications and guidelines to determine the appropriate load capacity for the gear rack.

- Proper Installation: Ensure that the spur gear rack is correctly installed according to the manufacturer’s instructions. Improper installation can result in misalignment, which may cause excessive wear, noise, and reduced performance. Follow proper alignment procedures and use appropriate tools and techniques to secure the gear rack in place. If unsure, consult with a qualified professional or the manufacturer for guidance.

- Noise and Vibration: Spur gear racks can generate noise and vibration during operation. Excessive noise and vibration may indicate issues such as misalignment, inadequate lubrication, or worn-out components. Regularly monitor the gear rack system for unusual noise or excessive vibration and promptly investigate and address any potential problems to avoid safety hazards and equipment failure.

- Training and Awareness: Ensure that personnel working with spur gear racks receive appropriate training and instructions on safe operating procedures. Familiarize them with the potential hazards associated with gear rack systems and educate them on how to safely perform tasks such as maintenance, inspection, and troubleshooting. Encourage a safety-conscious culture and promote awareness of potential risks.

- Emergency Stop and Shutdown: Make sure that the equipment or machinery integrated with the spur gear rack has emergency stop mechanisms in place. Clearly label and identify emergency stop buttons or switches and ensure that personnel know their locations and how to use them. Regularly test the emergency stop function to verify its effectiveness. In case of any abnormalities or emergencies, immediately initiate the shutdown procedure and follow appropriate safety protocols.

- Protective Equipment: When working with spur gear racks, it is advisable to wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and protective clothing. PPE can provide an additional layer of protection against potential hazards, such as flying debris, sharp edges, or accidental contact with moving parts.

These safety considerations are essential for maintaining a safe working environment when dealing with spur gear racks. By following proper safety practices, personnel can minimize the risk of accidents, ensure the longevity of the equipment, and promote a culture of safety within the workplace.

How do spur gear racks contribute to load distribution and control?

Spur gear racks play a crucial role in load distribution and control in various mechanical systems. Their design and engagement with pinion gears allow for efficient power transmission, load sharing, and control over the movement of loads. Here’s a detailed explanation of how spur gear racks contribute to load distribution and control:

- Load Transmission: Spur gear racks are designed to transmit rotational motion into linear motion. When a pinion gear engages with the gear teeth on the rack, the rotational force applied to the pinion is converted into linear motion along the rack’s length. This allows for the transfer of torque and power from the pinion to the rack, enabling the distribution of loads along the rack’s teeth.

- Load Sharing: In systems with multiple spur gear racks, load sharing occurs as the load is distributed among the engaged gear racks. For example, in a rack and pinion steering system, the torque applied to the steering wheel is transmitted to the pinion gear, which in turn engages with the rack. As the rack moves linearly, the load is distributed evenly among the teeth of the engaged rack sections, ensuring balanced force distribution and smooth operation.

- Force Control: By varying the input torque or adjusting the engagement between the pinion gear and the gear rack, the force applied to the rack can be controlled. This allows for precise force control in applications such as steering systems or adjustable suspension systems. By adjusting the force applied to the gear rack, the sensitivity and responsiveness of the system can be fine-tuned, providing the desired level of control and feedback to the user.

- Position Control: Spur gear racks enable precise position control of loads. By driving the pinion gear with a motor or actuator, the linear movement of the gear rack can be accurately controlled. This is important in applications such as seat adjustments, window mechanisms, or convertible top actuation, where precise positioning is required. Gear racks provide a reliable and repeatable means of achieving the desired linear displacement with high positional accuracy.

- Load Capacity: Spur gear racks are designed to handle high loads and distribute them evenly along the teeth of the rack. The tooth geometry and the material properties of the gear rack are carefully selected to ensure sufficient strength and load-carrying capacity. This allows spur gear racks to efficiently distribute and control loads, making them suitable for applications that involve heavy loads, such as steering systems or industrial machinery.

- Noise and Vibration Control: Properly designed spur gear racks with accurate tooth profiles and precise engagement can help reduce noise and vibration. The smooth and continuous meshing of the pinion gear with the gear rack minimizes backlash and unwanted movement, resulting in quieter operation. Additionally, gear racks can be designed with features such as tooth modifications or damping mechanisms to further reduce noise and vibration levels.

In summary, spur gear racks contribute to load distribution and control by transmitting torque and power, sharing loads among engaged racks, allowing for force and position control, handling high loads, and reducing noise and vibration. Their precise and reliable operation makes them valuable components in various mechanical systems where load distribution, control, and precise positioning are essential.

In which industries are spur gear racks typically used?

Spur gear racks find application in a wide range of industries due to their versatility and ability to convert rotational motion into linear motion. Some of the industries where spur gear racks are typically used include:

- Automotive: The automotive industry extensively utilizes spur gear racks in various applications. Rack and pinion steering systems in cars and trucks rely on spur gear racks for precise and responsive steering control. Additionally, spur gear racks are employed in automotive assembly lines, automated systems, and power transmission mechanisms.

- Aerospace and Defense: In the aerospace and defense sectors, spur gear racks are employed in diverse applications. They are used in aircraft control systems, missile guidance systems, radar systems, and various mechanisms requiring linear motion or power transmission. The reliability and precision offered by spur gear racks make them suitable for critical aerospace and defense applications.

- Industrial Machinery: Spur gear racks are widely used in industrial machinery across different sectors. They are found in packaging machines, printing presses, textile machinery, material handling systems, and other equipment requiring linear motion, precise positioning, or power transmission. Industrial machinery relies on spur gear racks for efficient and reliable operation.

- Robotics and Automation: In the fields of robotics and automation, spur gear racks play a crucial role. They are employed in robotic arms, automated manufacturing systems, pick-and-place machines, and various other automated mechanisms. Spur gear racks provide the necessary linear motion and precise positioning required for accurate and repeatable operations in these industries.

- Machine Tools: Spur gear racks are commonly used in machine tools such as milling machines, lathes, drilling machines, and CNC systems. They enable precise movement and positioning of cutting tools or workpieces, contributing to the accuracy and quality of machining operations. Spur gear racks are integral to the performance of machine tools.

- Material Handling and Logistics: The material handling and logistics industry heavily relies on spur gear racks for conveyors, lifts, and other linear motion systems. They are used in automated warehouses, distribution centers, baggage handling systems at airports, and various other material handling applications. Spur gear racks enable efficient movement and positioning of goods and materials.

- Medical Equipment: Spur gear racks are utilized in medical equipment and devices for precise motion control and positioning. They find applications in medical imaging systems, robotic surgical equipment, patient positioning systems, and laboratory automation. The accuracy and reliability of spur gear racks contribute to the performance and safety of medical devices.

- Renewable Energy: The renewable energy sector, particularly in wind turbines and solar tracking systems, employs spur gear racks. In wind turbines, spur gear racks enable the adjustment of blade pitch, allowing optimal capturing of wind energy. Solar tracking systems utilize spur gear racks to orient solar panels for maximizing energy absorption from sunlight.

These are just a few examples of the industries where spur gear racks are typically used. The versatility and functionality of spur gear racks make them applicable in numerous other industries, ranging from consumer electronics to mining and beyond. The specific requirements of each industry determine the design, size, and load capacity of spur gear racks used in their respective applications.

editor by Dream 2024-05-15

China high quality Flexible Rack and Pinion Gears cycle gear

Product Description

Product Description

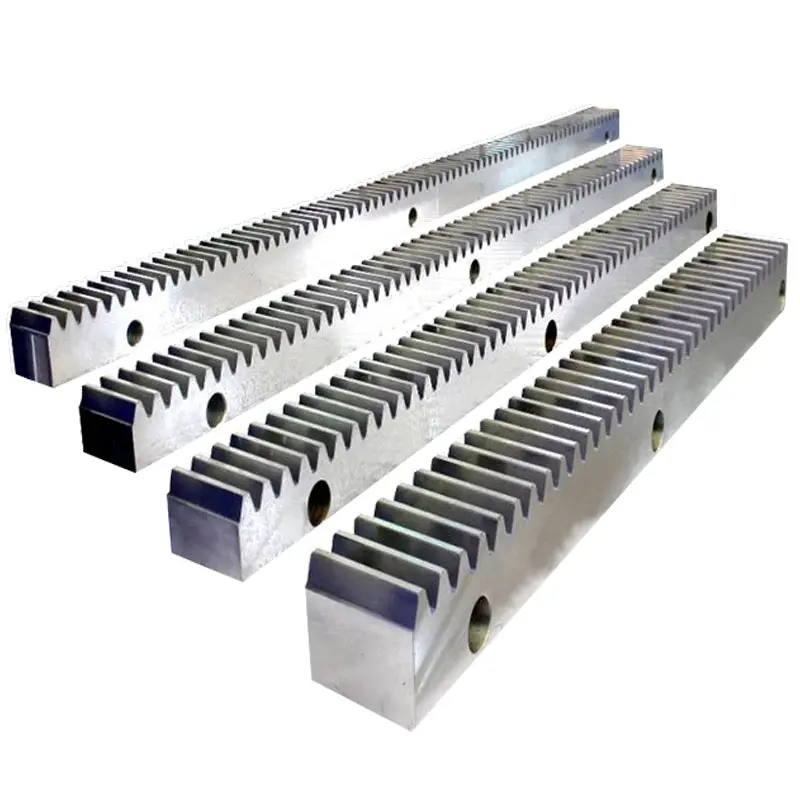

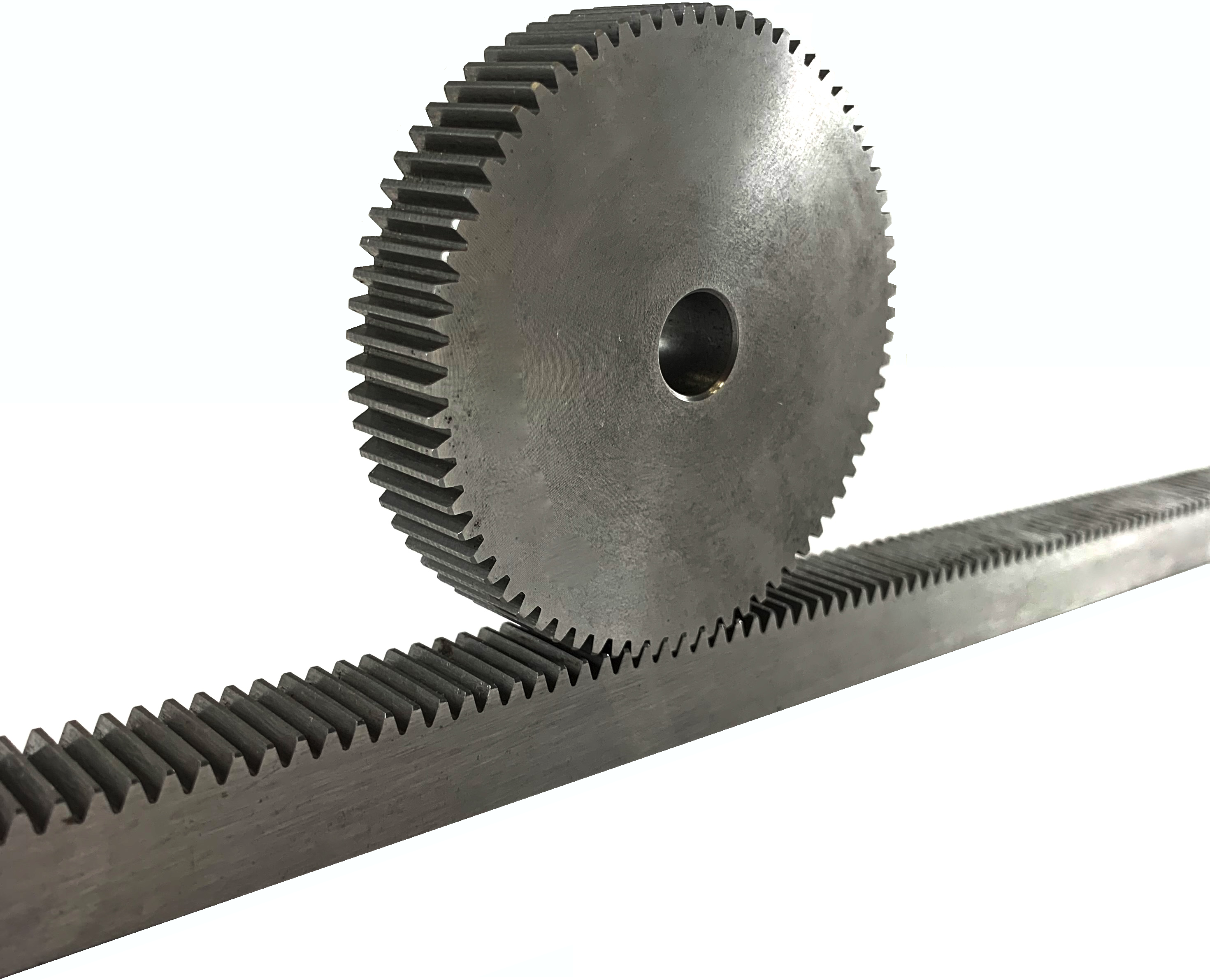

Gear Rack,

Rack from M1, 15*15*1000 to M8 30*30*2000

Our Advantages

WHY CHOOSE US

Comprehensive Product Portfolio We produce and supply a wide range of power transmission

products including drive chains, leaf chains, conveyor chains, agricultural chains, sprockets, and

couplings. This one-store-for-all shopping experience will significantly reduce your searching costs while

guarantee youfind what you want at 1 click.

Value Choice Products Our products are the best combination of quality and price, and you get what

you want within your budgets

Seasoned Sales Associates and Engineers We have 15 seasoned sales associates and 5 engineers;

on our team at your disposal any time when you need a helping hand. They are well trained with industry

know-now and will always respond to your requests within 24 hours.

100% Customer Retention Rate Our regular customers from overseas come back not just for our

premium quality products, but for the superior services that we’ve provided over the years.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | Flame-Retardant, Anti-Static |

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do spur gear racks contribute to efficient and precise linear motion?

Spur gear racks play a significant role in achieving efficient and precise linear motion in various mechanical systems. They offer several advantages that contribute to the overall performance and accuracy of linear motion mechanisms. Here’s how spur gear racks contribute to efficient and precise linear motion:

- Direct Conversion of Rotational to Linear Motion: Spur gear racks provide a direct conversion of rotational motion into linear motion. When a spur gear, known as a pinion, meshes with the gear rack, the rotary motion of the pinion is translated into linear motion along the rack’s length. This direct conversion eliminates the need for additional mechanisms or complex linkages, reducing energy losses and improving overall efficiency.

- High Efficiency: Spur gear racks are known for their high mechanical efficiency. The teeth of the gear rack and pinion mesh in a straight line, resulting in efficient power transmission with minimal energy losses. The involute tooth profile commonly used in spur gear systems ensures gradual and smooth tooth engagement, reducing friction and minimizing power wastage. This high efficiency contributes to the overall energy efficiency of the linear motion system.

- Precise Positioning: Spur gear racks offer precise positioning capabilities, making them suitable for applications that require accurate linear motion. The teeth of the gear rack and pinion provide positive engagement, ensuring precise and repeatable positioning along the rack’s length. This allows for accurate control and positioning of loads, making spur gear racks suitable for applications such as CNC machines, robotics, and precision positioning systems.

- Low Backlash: Backlash refers to the slight clearance or play between mating gears. Spur gear racks can be designed with minimal backlash, ensuring accurate and responsive linear motion. The teeth of the gear rack and pinion engage tightly, minimizing any undesirable movement or backlash during direction changes or load reversals. Low backlash contributes to the system’s precision, especially in applications where accurate positioning and control are critical.

- Load Distribution: Spur gear racks distribute the load over a larger contact area compared to other linear motion mechanisms. The multiple teeth along the rack’s length distribute the load evenly, reducing stress concentrations and enhancing load-carrying capacity. This load distribution capability allows for the handling of higher loads while maintaining smooth and precise linear motion.

- Modularity and Scalability: Spur gear racks offer modularity and scalability, making them adaptable to various system requirements. Gear racks can be easily extended or shortened to achieve the desired linear travel distance. Additionally, multiple gear racks can be combined or stacked to achieve longer travel distances or parallel linear motion. This modularity and scalability make spur gear racks versatile and suitable for a wide range of applications.

- Reliability and Durability: Spur gear racks are known for their reliability and durability. The simple and robust design of gear racks, combined with proper lubrication and maintenance, ensures long-term performance and minimal downtime. Spur gear racks can withstand high loads, operate under demanding conditions, and provide consistent linear motion over extended periods, contributing to the overall reliability and durability of the linear motion system.

By leveraging the advantages offered by spur gear racks, engineers and designers can achieve efficient, precise, and reliable linear motion in a wide range of applications. The selection of suitable gear rack materials, tooth profiles, and proper maintenance practices further enhance the performance and longevity of the linear motion system.

Can spur gear racks be applied in automotive applications, and if so, how?

Yes, spur gear racks can be widely applied in automotive applications, playing essential roles in various systems and components. Their durable and reliable characteristics make them suitable for different automotive functions. Here’s a detailed explanation of how spur gear racks can be utilized in automotive applications:

- Steering Systems: One of the primary applications of spur gear racks in automobiles is in steering systems. Gear racks are used in rack and pinion steering systems to convert rotational motion from the steering wheel into linear motion to control the direction of the wheels. The gear rack is mounted on the steering shaft, and as the pinion gear rotates, it engages with the gear teeth on the rack, causing the rack to move linearly and turn the wheels accordingly. Spur gear racks offer accurate and responsive steering, ensuring safe and reliable maneuverability.

- Seat Adjustments: Spur gear racks are also employed in automotive seat adjustment mechanisms. They enable the linear positioning of seats to accommodate different driver and passenger preferences. Gear racks, along with a pinion gear or motor, are used to achieve the desired seat height adjustment, forward and backward movement, and reclining angles. The gear rack system provides smooth and precise seat adjustments, enhancing comfort and ergonomics in vehicles.

- Window and Sunroof Mechanisms: Gear racks are utilized in automotive window and sunroof mechanisms to provide controlled and reliable linear motion. The gear rack, along with a motor or manual crank, enables the raising and lowering of windows or the opening and closing of sunroofs. Spur gear racks ensure smooth and synchronized movement of the window or sunroof panels, enhancing convenience and ventilation in vehicles.

- Convertible Top Actuation: In convertible vehicles, spur gear racks are employed in the actuation of the convertible top mechanism. The gear rack, driven by a motor or hydraulic system, facilitates the controlled extension or retraction of the convertible top. Spur gear racks offer precise and synchronized linear motion, ensuring smooth and reliable operation of the convertible top mechanism.

- Transmission Systems: Spur gear racks can be utilized in certain automotive transmission systems, particularly in manual transmissions. Gear racks, along with a shifting mechanism, enable the linear movement of gears to engage different gear ratios. By sliding the gear rack, the transmission system achieves the desired gear selection, allowing for smooth and efficient power transfer from the engine to the wheels.

- Chassis and Suspension Systems: Spur gear racks can be employed in automotive chassis and suspension systems to facilitate various movements and adjustments. For example, they can be used in adjustable suspension systems to control the ride height and stiffness of the vehicle. Gear racks, along with hydraulic or electronic actuators, allow for precise and dynamic adjustments, enhancing handling, stability, and comfort in different driving conditions.

Overall, spur gear racks are essential components in automotive applications, providing reliable and precise linear motion in steering systems, seat adjustments, window and sunroof mechanisms, convertible top actuation, transmission systems, and chassis/suspension systems. Their robust construction and ability to handle high loads make them suitable for the demanding requirements of the automotive industry.

In which industries are spur gear racks typically used?

Spur gear racks find application in a wide range of industries due to their versatility and ability to convert rotational motion into linear motion. Some of the industries where spur gear racks are typically used include:

- Automotive: The automotive industry extensively utilizes spur gear racks in various applications. Rack and pinion steering systems in cars and trucks rely on spur gear racks for precise and responsive steering control. Additionally, spur gear racks are employed in automotive assembly lines, automated systems, and power transmission mechanisms.

- Aerospace and Defense: In the aerospace and defense sectors, spur gear racks are employed in diverse applications. They are used in aircraft control systems, missile guidance systems, radar systems, and various mechanisms requiring linear motion or power transmission. The reliability and precision offered by spur gear racks make them suitable for critical aerospace and defense applications.

- Industrial Machinery: Spur gear racks are widely used in industrial machinery across different sectors. They are found in packaging machines, printing presses, textile machinery, material handling systems, and other equipment requiring linear motion, precise positioning, or power transmission. Industrial machinery relies on spur gear racks for efficient and reliable operation.

- Robotics and Automation: In the fields of robotics and automation, spur gear racks play a crucial role. They are employed in robotic arms, automated manufacturing systems, pick-and-place machines, and various other automated mechanisms. Spur gear racks provide the necessary linear motion and precise positioning required for accurate and repeatable operations in these industries.

- Machine Tools: Spur gear racks are commonly used in machine tools such as milling machines, lathes, drilling machines, and CNC systems. They enable precise movement and positioning of cutting tools or workpieces, contributing to the accuracy and quality of machining operations. Spur gear racks are integral to the performance of machine tools.

- Material Handling and Logistics: The material handling and logistics industry heavily relies on spur gear racks for conveyors, lifts, and other linear motion systems. They are used in automated warehouses, distribution centers, baggage handling systems at airports, and various other material handling applications. Spur gear racks enable efficient movement and positioning of goods and materials.

- Medical Equipment: Spur gear racks are utilized in medical equipment and devices for precise motion control and positioning. They find applications in medical imaging systems, robotic surgical equipment, patient positioning systems, and laboratory automation. The accuracy and reliability of spur gear racks contribute to the performance and safety of medical devices.

- Renewable Energy: The renewable energy sector, particularly in wind turbines and solar tracking systems, employs spur gear racks. In wind turbines, spur gear racks enable the adjustment of blade pitch, allowing optimal capturing of wind energy. Solar tracking systems utilize spur gear racks to orient solar panels for maximizing energy absorption from sunlight.

These are just a few examples of the industries where spur gear racks are typically used. The versatility and functionality of spur gear racks make them applicable in numerous other industries, ranging from consumer electronics to mining and beyond. The specific requirements of each industry determine the design, size, and load capacity of spur gear racks used in their respective applications.

editor by Dream 2024-05-14

China Standard Factory Supply M1-M12 Customized Steel Flexible Window Round Gear Rack wholesaler

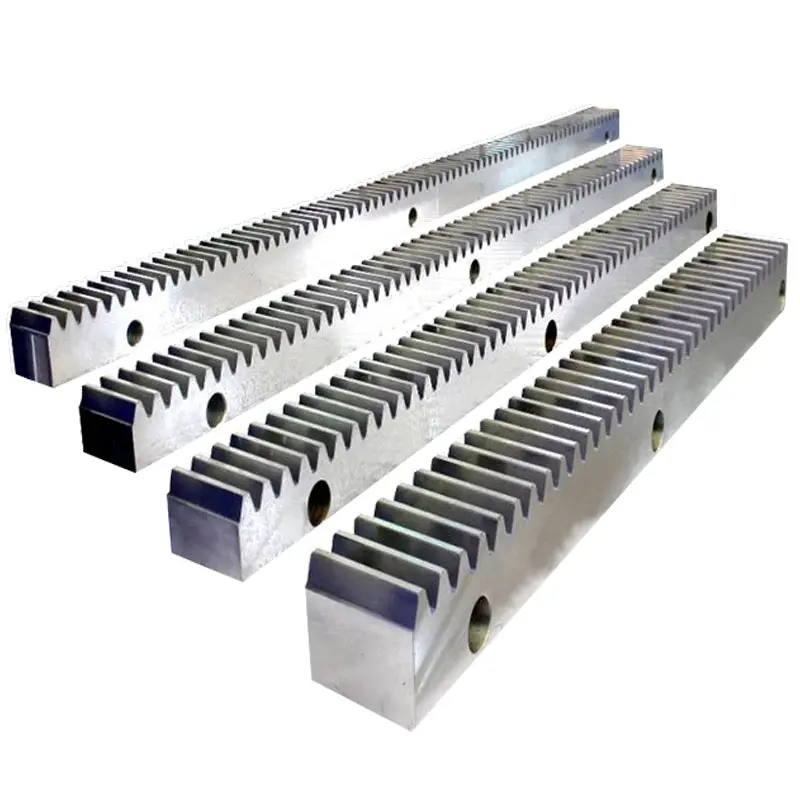

Product Description

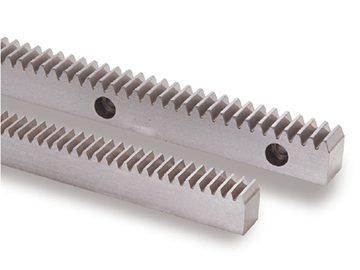

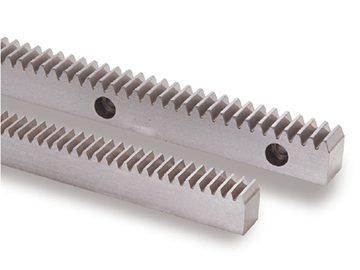

| Product description |

Industrial Gear Rack

1.Zinc Plated/Blacken Spur Helical Gear Rack

2.C45/40CR material

3.High precision to Din 7 8 9

4.Four sides grind surface treatment

5.Pressure angle of 20°

6.Hardness:HB 190-250

Gear Rack type

Length X Width X Height (MM)

Material A3 45# and stainless steel

M1 15X15X1000

M1.5 17X17X1000

M2 20X20X1000

M2.5 25X25X1000

M3 30X30X1000

M4 40X40X1000

M5 50X50X1000

M6 60X60X1000

M8 80X80X1000 etc

If you need 2M or 3M, or any other length, we can produce as per your requests

Most of our customer will send us drawing and we can produce as per your drawing or sample.

We produce Module M1-M8 racks, CP and DP British standard racks. The maximum length of the rack is 2 meters. Our products have been widely used in many fields such as automatic doors, window openers, engraving machines, lifters, escalators, automated warehousing, food machinery, power tools, machine tools, precision transmission, etc.

We exported gear rack in big quantity to Europe, America, Australia, Brazil, South Africa, Russia etc. There is standard gear rack available and also special gear rack as per your drawing or samples. Our gear racks produced by CNC machines.

Our gear racks are used for window machine, engraving machine, lift machine, opener rack, CNC machine, automobile, industrial usage so on.

We can also supply Construction lift gear rack,American standard gears racks,steel gear rack,helical gear rack,flexible gear racks,power steering rack,steering gear rack ,stainless steel gear rack ,round rack gear ,nylon gear rack ,spur gear rack ,boston gear rack ,audia gear rack ,gears racks ,rack and pinion gear.

HangZhou CHINAMFG Industry Co., Ltd. is a specialized supplier of a full range of chains, sprockets, gears, gear racks, v belt pulley, timing pulley, V-belts, couplings, machined parts and so on.

Due to our CHINAMFG in offering best service to our clients, understanding of your needs and overriding sense of responsibility toward filling ordering requirements, we have obtained the trust of buyers worldwide. Having accumulated precious experience in cooperating with foreign customers, our products are selling well in the American, European, South American and Asian markets.Our products are manufactured by modern computerized machinery and equipment. Meanwhile, our products are manufactured according to high quality standards, and complying with the international advanced standard criteria.

With many years’ experience in this line, we will be trusted by our advantages in competitive price, one-time delivery, prompt response, on-hand engineering support and good after-sales services.

Additionally, all our production procedures are in compliance with ISO9001 standards. We also can design and make non-standard products to meet customers’ special requirements. Quality and credit are the bases that make a corporation alive. We will provide best services and high quality products with all sincerity. If you need any information or samples, please contact us and you will have our soon reply.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do spur gear racks contribute to efficient and precise linear motion?

Spur gear racks play a significant role in achieving efficient and precise linear motion in various mechanical systems. They offer several advantages that contribute to the overall performance and accuracy of linear motion mechanisms. Here’s how spur gear racks contribute to efficient and precise linear motion:

- Direct Conversion of Rotational to Linear Motion: Spur gear racks provide a direct conversion of rotational motion into linear motion. When a spur gear, known as a pinion, meshes with the gear rack, the rotary motion of the pinion is translated into linear motion along the rack’s length. This direct conversion eliminates the need for additional mechanisms or complex linkages, reducing energy losses and improving overall efficiency.

- High Efficiency: Spur gear racks are known for their high mechanical efficiency. The teeth of the gear rack and pinion mesh in a straight line, resulting in efficient power transmission with minimal energy losses. The involute tooth profile commonly used in spur gear systems ensures gradual and smooth tooth engagement, reducing friction and minimizing power wastage. This high efficiency contributes to the overall energy efficiency of the linear motion system.

- Precise Positioning: Spur gear racks offer precise positioning capabilities, making them suitable for applications that require accurate linear motion. The teeth of the gear rack and pinion provide positive engagement, ensuring precise and repeatable positioning along the rack’s length. This allows for accurate control and positioning of loads, making spur gear racks suitable for applications such as CNC machines, robotics, and precision positioning systems.

- Low Backlash: Backlash refers to the slight clearance or play between mating gears. Spur gear racks can be designed with minimal backlash, ensuring accurate and responsive linear motion. The teeth of the gear rack and pinion engage tightly, minimizing any undesirable movement or backlash during direction changes or load reversals. Low backlash contributes to the system’s precision, especially in applications where accurate positioning and control are critical.

- Load Distribution: Spur gear racks distribute the load over a larger contact area compared to other linear motion mechanisms. The multiple teeth along the rack’s length distribute the load evenly, reducing stress concentrations and enhancing load-carrying capacity. This load distribution capability allows for the handling of higher loads while maintaining smooth and precise linear motion.

- Modularity and Scalability: Spur gear racks offer modularity and scalability, making them adaptable to various system requirements. Gear racks can be easily extended or shortened to achieve the desired linear travel distance. Additionally, multiple gear racks can be combined or stacked to achieve longer travel distances or parallel linear motion. This modularity and scalability make spur gear racks versatile and suitable for a wide range of applications.

- Reliability and Durability: Spur gear racks are known for their reliability and durability. The simple and robust design of gear racks, combined with proper lubrication and maintenance, ensures long-term performance and minimal downtime. Spur gear racks can withstand high loads, operate under demanding conditions, and provide consistent linear motion over extended periods, contributing to the overall reliability and durability of the linear motion system.

By leveraging the advantages offered by spur gear racks, engineers and designers can achieve efficient, precise, and reliable linear motion in a wide range of applications. The selection of suitable gear rack materials, tooth profiles, and proper maintenance practices further enhance the performance and longevity of the linear motion system.

How do spur gear racks handle variations in environmental conditions?

Spur gear racks are designed to handle variations in environmental conditions and maintain their performance and durability. They are engineered to withstand factors such as temperature fluctuations, moisture, dust, and other environmental challenges. Here’s a detailed explanation of how spur gear racks handle variations in environmental conditions:

- Material Selection: The choice of materials for spur gear racks is crucial in ensuring their resilience to environmental conditions. Common materials used for gear racks include steel alloys, stainless steel, and engineered plastics. These materials offer high strength, corrosion resistance, and thermal stability, enabling gear racks to withstand environmental challenges effectively.

- Surface Treatments: Spur gear racks can undergo surface treatments to enhance their resistance to environmental conditions. For example, gear racks can be coated or plated with materials such as zinc, nickel, or chrome to provide corrosion resistance and improve durability. These surface treatments form a protective barrier, safeguarding the gear racks from moisture, chemicals, and abrasive particles.

- Lubrication: Proper lubrication is essential for the smooth operation and longevity of spur gear racks, especially in varying environmental conditions. Lubricants reduce friction, prevent wear, and protect against corrosion. The selection of appropriate lubricants depends on the operating conditions and environmental factors. In extreme environments, specialized lubricants with high viscosity or additives may be used to ensure optimal gear rack performance.

- Sealing and Enclosure: Spur gear racks can be enclosed or sealed to protect them from environmental elements. Seals and enclosures prevent the ingress of moisture, dust, and contaminants, preserving the integrity and performance of the gear racks. Various sealing methods, such as gaskets, O-rings, or lip seals, can be employed to create a barrier against external elements.

- Heat Dissipation: Temperature variations can impact the performance of gear racks, especially in high-temperature environments. Proper heat dissipation mechanisms, such as cooling fans, heat sinks, or ventilation, can be incorporated to regulate the temperature and prevent overheating. Efficient heat dissipation helps maintain the dimensional stability of gear racks and prevents premature wear or distortion.

- Design Considerations: Gear rack designs can incorporate features that enhance their resilience to environmental conditions. For example, the inclusion of debris guards, labyrinth seals, or protective covers can prevent the accumulation of dirt, dust, or foreign particles. Additionally, gear rack designs can incorporate drainage channels or provisions for moisture egress to mitigate the effects of moisture and humidity.

- Maintenance and Inspection: Regular maintenance and inspection practices are essential to ensure the optimal performance of spur gear racks in varying environmental conditions. Periodic cleaning, lubrication replenishment, and visual inspections help identify any signs of wear, damage, or degradation caused by environmental factors. Timely maintenance and necessary repairs or replacements can prolong the lifespan of gear racks.

By employing suitable materials, surface treatments, lubrication practices, sealing mechanisms, and design considerations, spur gear racks can effectively handle variations in environmental conditions. It is crucial to consider the specific environmental challenges that gear racks may encounter in a particular application and apply appropriate measures to enhance their resilience and longevity.

What are the advantages of using spur gear racks in mechanical systems?

Spur gear racks offer several advantages when used in mechanical systems. These advantages contribute to their widespread use and popularity across various industries. Here are some key advantages of using spur gear racks:

- Efficient Power Transmission: Spur gear racks provide efficient power transmission between the rack and pinion gear. The straight teeth of the rack engage with the pinion gear, allowing for smooth and direct power transfer. This results in minimal power loss, making spur gear racks an efficient choice for transmitting rotational motion into linear motion or vice versa.

- Precise Linear Motion: Spur gear racks deliver precise and controlled linear motion. The teeth on the rack engage with the pinion gear, ensuring accurate movement along the length of the rack. This precision is essential in applications that require accurate positioning, such as CNC machines, robotics, and automated systems. Spur gear racks allow for repeatable and reliable motion control.

- High Load Capacity: Spur gear racks are designed to handle high load capacities. The straight tooth design and the wide contact area between the rack and pinion gear enable them to withstand substantial forces. This makes spur gear racks suitable for applications that involve heavy loads or high torque requirements, such as material handling systems, industrial machinery, and automotive components.

- Simple and Compact Design: Spur gear racks have a relatively simple and compact design. They consist of a straight bar with teeth along one side, along with a pinion gear. This simplicity makes spur gear racks easy to manufacture, assemble, and maintain. The compact design allows for efficient space utilization in mechanical systems, making them suitable for applications with limited space constraints.

- Cost-Effective: Spur gear racks are cost-effective compared to other types of gearing systems. Their simple design and ease of manufacturing contribute to lower production costs. Additionally, spur gear racks have a long service life and require minimal maintenance, reducing overall operating costs. These factors make spur gear racks a cost-efficient choice for many mechanical systems.

- Versatility: Spur gear racks are highly versatile and can be used in a wide range of applications. From automotive steering systems to industrial machinery and robotics, spur gear racks find utility in numerous industries. They can be customized to meet specific requirements by adjusting parameters such as gear ratios, tooth profiles, and materials. The versatility of spur gear racks makes them adaptable to various mechanical systems.

- Reliability and Durability: Spur gear racks are known for their reliability and durability. The design and tooth engagement of spur gear racks ensure robust performance and resistance to wear and tear. When properly lubricated and maintained, spur gear racks can operate smoothly and reliably for extended periods. This reliability and durability make spur gear racks suitable for demanding applications that require continuous and dependable operation.

These advantages make spur gear racks a popular choice in mechanical systems that require efficient power transmission, precise linear motion, high load capacity, and cost-effectiveness. The simplicity, versatility, and reliability of spur gear racks make them a fundamental component in various industries and applications.

editor by Dream 2024-05-14

China Hot selling Durable High Quality Heavy Duty 12mm Iron Gear Rail Sliding Door Flexible Rack and Pinion Steel Gear Rack with high quality

Product Description

Product Description

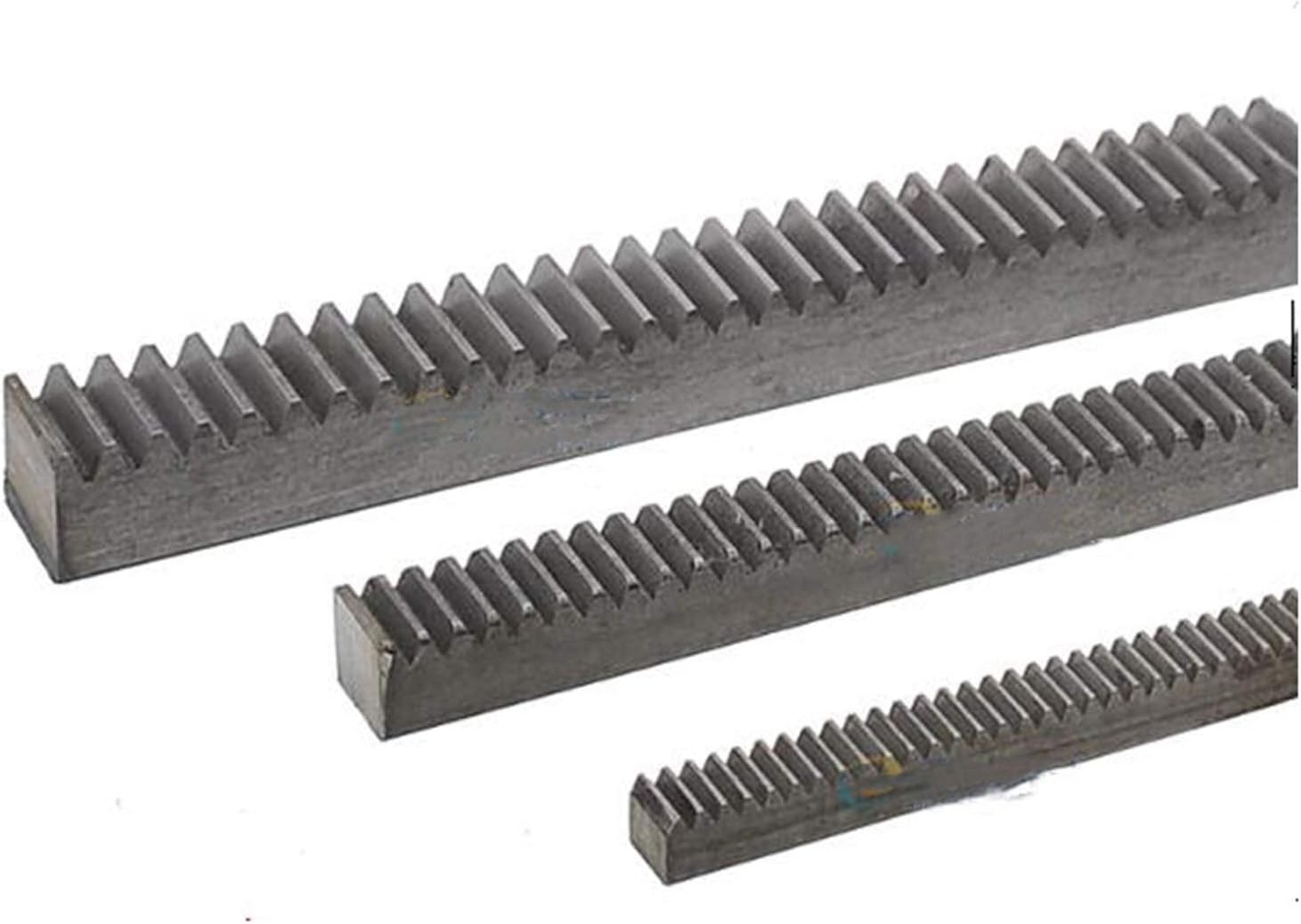

Iron gear rack

Made of Q235 steel for sliding doors, It is usually used with a door motor. Our products are exported to Southeast Asia, Europe, South America, etc. Reliable quality, Each piece of gear rack has screws, as shown below.

You are warmly welcome to send us an inquiry for detailed information.

| Product Name | Specification | Modulus | Material |

| Nylon Rack | 2 Eyes Light | M4 | PA66 |

| Nylon Rack | 2 Eyes Heavy | M4 | PA66 |

| Nylon Rack | 4 Eyes Light | M4 | PA66 |

| Nylon Rack | 6 Eyes Heavy | M4 | PA66 |

| Iron Rack | 8*30*1005 | M4 | Q235 |

| Iron Rack | 8*30*1998 | M4 | Q235 |

| Iron Rack | 9*30*1005 | M4 | Q235 |

| Iron Rack | 10*30*1005 | M4 | Q235 |

| Iron Rack | 10*30*1998 | M4 | Q235 |

| Iron Rack | 11*30*1005 | M4 | Q235 |

| Iron Rack | 11*30*1998 | M4 | Q235 |

| Iron Rack | 12*30*1005 | M4 | Q235 |

| Iron Rack | 12*30*1998 | M4 | Q235 |

| Iron Rack | 22*22*1005 | M4 | Q235 |

| Iron Rack | 22*22*1998 | M4 | Q235 |

| Iron Rack | 30*30*998 | M6 | Q235 |

| Iron Rack | 30*30*1998 | M6 | Q235 |

Company Profile

Main Products

Production Process

Packaging & Shipping

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Color: | Fixed |

|---|---|

| Customized: | Customized |

| Standard: | International |

| Type: | Connection |

| Material: | Iron |

| Modulus: | M4 |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How does a spur gear rack handle variations in linear motion and power transmission?

A spur gear rack is designed to effectively handle variations in linear motion and power transmission in mechanical systems. Its specific features and characteristics enable it to accommodate different requirements and challenges. Let’s explore how a spur gear rack handles these variations:

Linear Motion: A spur gear rack is optimized for converting rotational motion into linear motion or vice versa. The teeth on the rack mesh with a pinion gear, which transfers rotational motion to the linear movement of the rack. The design of the rack ensures smooth and precise linear motion by maintaining constant contact between the teeth of the rack and the pinion gear. This consistent contact allows for accurate and controlled movement along the length of the rack, effectively handling variations in linear motion.

The pitch of the spur gear rack, which refers to the distance between consecutive teeth, determines the linear motion achieved per revolution of the pinion gear. By selecting an appropriate pitch, variations in linear motion can be accommodated. For example, a rack with a smaller pitch will provide finer and more precise linear motion, while a rack with a larger pitch will offer faster linear motion over a given distance. The flexibility to choose the appropriate pitch allows for customization and adaptation to specific linear motion requirements in different applications.

Power Transmission: Spur gear racks are designed to handle variations in power transmission efficiently. The straight teeth of the rack engage with the pinion gear, ensuring direct and efficient transfer of rotational power. The teeth of the rack are designed to distribute the load evenly along the contact area with the pinion gear, minimizing stress concentrations and reducing the risk of tooth failure. This design feature enables spur gear racks to transfer power reliably and handle variations in power transmission.

The load capacity of a spur gear rack depends on various factors, including the size and material of the rack, the tooth profile, and the quality of tooth engagement with the pinion gear. By appropriately selecting these parameters, spur gear racks can be designed to handle different levels of power transmission requirements. The robust construction and tooth geometry of the rack allow it to withstand high loads, ensuring reliable power transmission even in demanding applications.

Furthermore, spur gear racks can be combined with multiple pinion gears or gear trains to distribute power across multiple racks or achieve complex motion systems. This allows for the handling of variations in power transmission by dividing the load or adjusting the gear ratios to suit specific needs.

In summary, spur gear racks effectively handle variations in linear motion and power transmission through their design features and the ability to customize parameters such as pitch, tooth profile, and load capacity. The precise and controlled linear motion, along with efficient power transmission, makes spur gear racks a reliable choice for a wide range of mechanical systems.

What materials are commonly used in the construction of spur gear racks?

In the construction of spur gear racks, several materials are commonly used to ensure strength, durability, and efficient performance. The choice of material depends on factors such as the specific application requirements, operating conditions, and budget constraints. Here are some materials commonly used in the construction of spur gear racks:

- Steel Alloys: Steel alloys, such as carbon steel and alloy steel, are widely employed in the construction of spur gear racks. These materials offer excellent strength, hardness, and wear resistance. Carbon steel, such as SAE 1045 or 1050, is commonly used for gear racks due to its high tensile strength and affordability. Alloy steels, such as 8620 or 4140, provide enhanced mechanical properties and are utilized in applications requiring higher load-carrying capacity or increased toughness.

- Stainless Steel: Stainless steel is another popular material choice for spur gear racks, especially in applications where corrosion resistance is crucial. Stainless steel alloys, such as AISI 300 series (e.g., 304 or 316), offer excellent resistance to moisture, chemicals, and atmospheric corrosion. These materials are commonly used in food processing equipment, marine applications, or environments with high humidity or exposure to corrosive substances.

- Cast Iron: Cast iron is utilized in the construction of gear racks when high strength and wear resistance are required. Gray cast iron (e.g., ASTM A48 Class 40) is commonly used due to its good machinability, damping properties, and ability to withstand heavy loads. Cast iron gear racks are often employed in industrial machinery, power transmission systems, and applications with demanding operating conditions.

- Plastics: Engineered plastics, such as nylon (polyamide) and acetal (polyoxymethylene), are used in applications where noise reduction, self-lubrication, and resistance to chemical corrosion are desirable. Plastic gear racks offer advantages such as lightweight, low friction, and the ability to run without additional lubrication. They find applications in industries like automotive, consumer electronics, and medical equipment.

- Bronze and Brass: Bronze and brass alloys are utilized in specific applications that require excellent machinability, low friction, and resistance to wear. Phosphor bronze (e.g., ASTM B139) and brass (e.g., ASTM B16) are commonly used for gear racks in applications such as musical instruments, clocks, and low-load precision machinery.

It’s important to note that the selection of the appropriate material for a spur gear rack depends on various factors, including the specific application requirements, load conditions, operating temperatures, and environmental factors. Engineers and designers consider these factors to determine the most suitable material that will provide the necessary strength, durability, and performance for the intended application.

What is a spur gear rack, and how does it function?

A spur gear rack is a type of gear mechanism that consists of a straight, flat toothed bar called a rack and a cylindrical gear called a pinion. It is commonly used in various mechanical systems to convert rotational motion into linear motion or vice versa.

The rack is a long, straight bar with teeth along one side. These teeth are usually straight and parallel to the rack’s axis. The pinion, on the other hand, is a small cylindrical gear with teeth that mesh with the teeth on the rack. The pinion is mounted parallel to the rack and engages with the rack by rotating against it.

The functioning of a spur gear rack is relatively simple. When the pinion gear rotates, its teeth engage with the teeth on the rack. As the pinion rotates, it causes the rack to move linearly along its length. This linear motion can be used to drive other mechanisms or to convert linear motion into rotational motion.

For example, in a rack and pinion steering system in automobiles, the rotation of the steering wheel is converted into linear motion of the rack. This linear motion is then used to steer the vehicle’s wheels. Similarly, in some machine tools, the linear motion of the rack is used to position a cutting tool or a workpiece.

The teeth on the rack and pinion gear are designed in a way that ensures smooth and efficient transfer of motion. The teeth mesh tightly, minimizing backlash and providing accurate and precise motion transfer. The size and shape of the teeth can vary depending on the specific application and requirements.

In summary, a spur gear rack is a gear mechanism that utilizes a straight toothed bar (rack) and a cylindrical gear (pinion) to convert rotational motion into linear motion or vice versa. It is widely used in various mechanical systems for its simplicity, efficiency, and versatility.

editor by Dream 2024-05-13

China Hot selling Spur Gear Rack Great Quality Ground Linear Flexible Industrial Manufacturer Stainless Steel Helical Spur POM Plastic and Pinion Steering Metric Pinion Gear Rack with Great quality

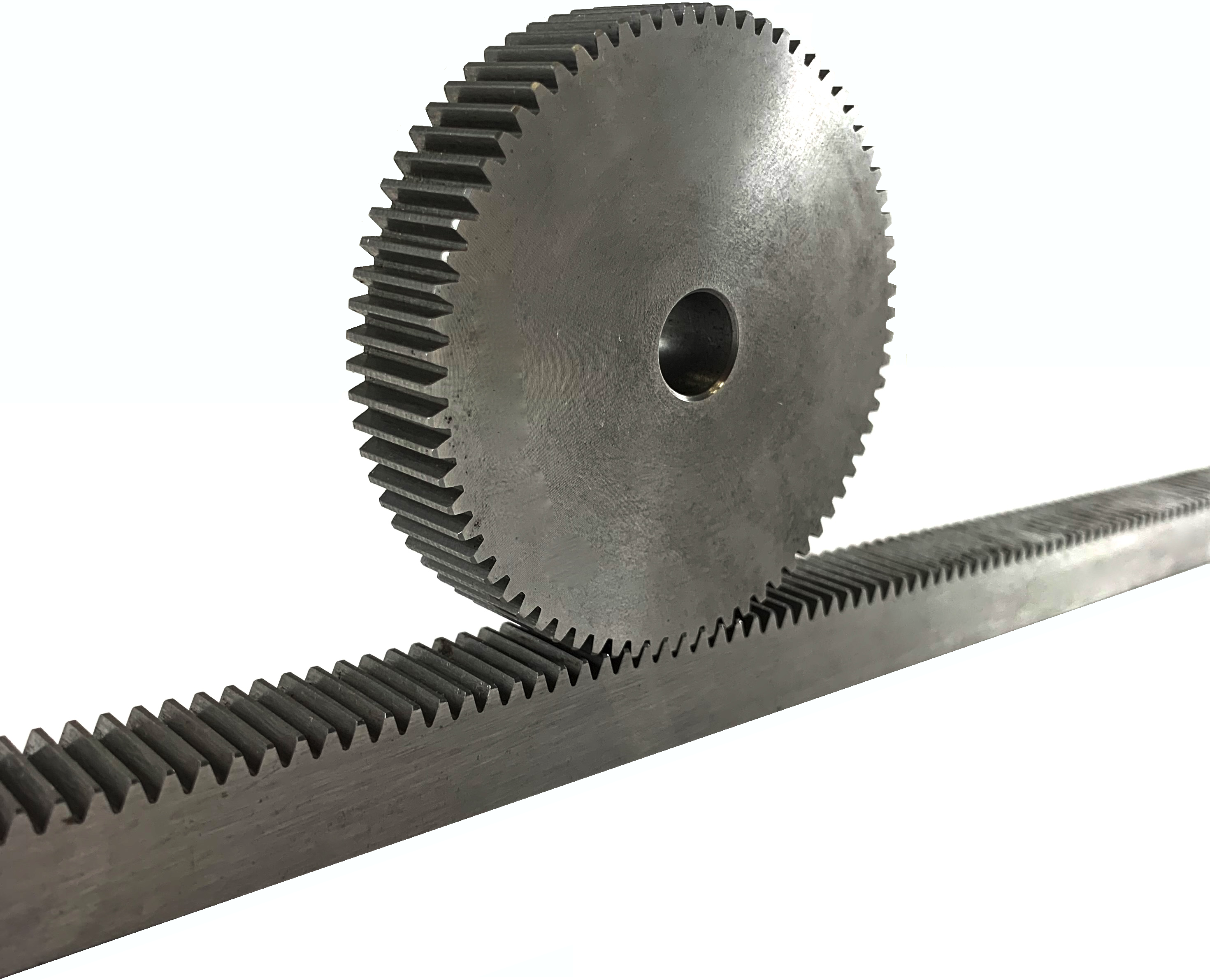

Product Description

Spur Gear Rack Great Quality Ground Linear Flexible Industrial Manufacturer Stainless Steel Helical Spur POM Plastic and Pinion Steering Metric pinion Gear Rack

spur gear rack

Material: carbon steel such as C45, 20CrMnTi, 40Cr, 42CrMo or stainless steel or copper or nylon and so on

Heat Treatment: Hardening and Tempering, High Frequency Quenching, Carburizing Quenching and so on.

Standard: European or American standard

Item: M0.5,M1,M1.5,M1.7,M2,M2.5,M3,M4,M5,M6 and so on

Export Area: Europe and America

OEM service: make based on your special sample or drawing and meet your need for high precision on teeth of gear

The rack is a special gear with teeth distributed on the strip body. The racks are also divided into straight racks and helical racks, which are paired with spur gears and helical gears, respectively; the tooth profile of racks is straight rather than involute (it is flat for tooth surfaces) The equivalent of the circle radius of the inHangZhou cylinder is infinite.

The quality character of EP gear racks:

1. Stable transmission and low noise;

2. Effectively avoid normal tolerance based on high precision;

3. The surfaces can be ground to grade 7 quality, and teeth can be ground to grade 6 quality;

4. The mounting holes can be made as request;

5. The price is competitive even the quality is high.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Gear Rack |

|---|---|

| Certification: | CE, ISO9001: 2000 |

| Condition: | New |

| Warranty: | 1.5 Years |

| Processing: | Hobbing |

| Color: | as Request |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

How does a spur gear rack handle variations in linear motion and power transmission?

A spur gear rack is designed to effectively handle variations in linear motion and power transmission in mechanical systems. Its specific features and characteristics enable it to accommodate different requirements and challenges. Let’s explore how a spur gear rack handles these variations:

Linear Motion: A spur gear rack is optimized for converting rotational motion into linear motion or vice versa. The teeth on the rack mesh with a pinion gear, which transfers rotational motion to the linear movement of the rack. The design of the rack ensures smooth and precise linear motion by maintaining constant contact between the teeth of the rack and the pinion gear. This consistent contact allows for accurate and controlled movement along the length of the rack, effectively handling variations in linear motion.

The pitch of the spur gear rack, which refers to the distance between consecutive teeth, determines the linear motion achieved per revolution of the pinion gear. By selecting an appropriate pitch, variations in linear motion can be accommodated. For example, a rack with a smaller pitch will provide finer and more precise linear motion, while a rack with a larger pitch will offer faster linear motion over a given distance. The flexibility to choose the appropriate pitch allows for customization and adaptation to specific linear motion requirements in different applications.

Power Transmission: Spur gear racks are designed to handle variations in power transmission efficiently. The straight teeth of the rack engage with the pinion gear, ensuring direct and efficient transfer of rotational power. The teeth of the rack are designed to distribute the load evenly along the contact area with the pinion gear, minimizing stress concentrations and reducing the risk of tooth failure. This design feature enables spur gear racks to transfer power reliably and handle variations in power transmission.

The load capacity of a spur gear rack depends on various factors, including the size and material of the rack, the tooth profile, and the quality of tooth engagement with the pinion gear. By appropriately selecting these parameters, spur gear racks can be designed to handle different levels of power transmission requirements. The robust construction and tooth geometry of the rack allow it to withstand high loads, ensuring reliable power transmission even in demanding applications.

Furthermore, spur gear racks can be combined with multiple pinion gears or gear trains to distribute power across multiple racks or achieve complex motion systems. This allows for the handling of variations in power transmission by dividing the load or adjusting the gear ratios to suit specific needs.

In summary, spur gear racks effectively handle variations in linear motion and power transmission through their design features and the ability to customize parameters such as pitch, tooth profile, and load capacity. The precise and controlled linear motion, along with efficient power transmission, makes spur gear racks a reliable choice for a wide range of mechanical systems.

Can spur gear racks be applied in automotive applications, and if so, how?

Yes, spur gear racks can be widely applied in automotive applications, playing essential roles in various systems and components. Their durable and reliable characteristics make them suitable for different automotive functions. Here’s a detailed explanation of how spur gear racks can be utilized in automotive applications:

- Steering Systems: One of the primary applications of spur gear racks in automobiles is in steering systems. Gear racks are used in rack and pinion steering systems to convert rotational motion from the steering wheel into linear motion to control the direction of the wheels. The gear rack is mounted on the steering shaft, and as the pinion gear rotates, it engages with the gear teeth on the rack, causing the rack to move linearly and turn the wheels accordingly. Spur gear racks offer accurate and responsive steering, ensuring safe and reliable maneuverability.

- Seat Adjustments: Spur gear racks are also employed in automotive seat adjustment mechanisms. They enable the linear positioning of seats to accommodate different driver and passenger preferences. Gear racks, along with a pinion gear or motor, are used to achieve the desired seat height adjustment, forward and backward movement, and reclining angles. The gear rack system provides smooth and precise seat adjustments, enhancing comfort and ergonomics in vehicles.

- Window and Sunroof Mechanisms: Gear racks are utilized in automotive window and sunroof mechanisms to provide controlled and reliable linear motion. The gear rack, along with a motor or manual crank, enables the raising and lowering of windows or the opening and closing of sunroofs. Spur gear racks ensure smooth and synchronized movement of the window or sunroof panels, enhancing convenience and ventilation in vehicles.

- Convertible Top Actuation: In convertible vehicles, spur gear racks are employed in the actuation of the convertible top mechanism. The gear rack, driven by a motor or hydraulic system, facilitates the controlled extension or retraction of the convertible top. Spur gear racks offer precise and synchronized linear motion, ensuring smooth and reliable operation of the convertible top mechanism.

- Transmission Systems: Spur gear racks can be utilized in certain automotive transmission systems, particularly in manual transmissions. Gear racks, along with a shifting mechanism, enable the linear movement of gears to engage different gear ratios. By sliding the gear rack, the transmission system achieves the desired gear selection, allowing for smooth and efficient power transfer from the engine to the wheels.

- Chassis and Suspension Systems: Spur gear racks can be employed in automotive chassis and suspension systems to facilitate various movements and adjustments. For example, they can be used in adjustable suspension systems to control the ride height and stiffness of the vehicle. Gear racks, along with hydraulic or electronic actuators, allow for precise and dynamic adjustments, enhancing handling, stability, and comfort in different driving conditions.

Overall, spur gear racks are essential components in automotive applications, providing reliable and precise linear motion in steering systems, seat adjustments, window and sunroof mechanisms, convertible top actuation, transmission systems, and chassis/suspension systems. Their robust construction and ability to handle high loads make them suitable for the demanding requirements of the automotive industry.

How is a spur gear rack different from other types of gear racks?

A spur gear rack is a specific type of gear rack, distinguished by its straight teeth that are parallel to the axis of the rack. While other types of gear racks may have different tooth profiles or orientations, the main differences lie in their design and application.

Helical Gear Rack: Unlike spur gear racks, helical gear racks have teeth that are cut at an angle, forming a helix shape. This helical arrangement allows for smoother and quieter operation compared to spur gear racks. Helical gear racks are commonly used in applications where high precision, load capacity, and reduced noise are important, such as in CNC machines and industrial automation systems.